Intelligently conceived IoT applications can unlock great efficiencies and insights for businesses. The framework created by South African innovator IoT.nxt combines powerful software with the multi-functional Raptor™ intelligent edge platform to maximise value for clients. XJTAG’s effectiveness, efficiency and ease of use proved critical for cost-effectively developing the hardware in-house.

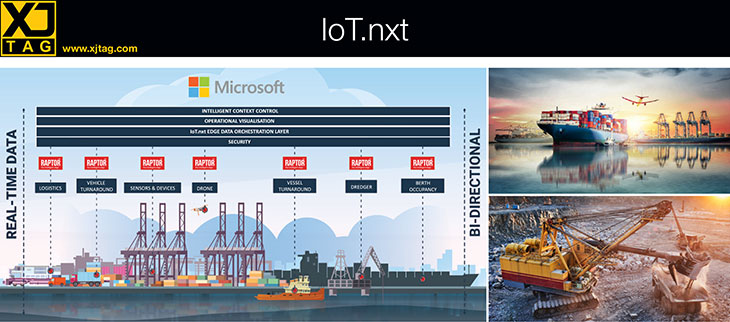

IoT.nxt based in Pretoria, South Africa, has created a technology-agnostic IoT framework that lets companies connect new and legacy enterprise equipment to unlock the value of the data generated every second throughout their organisations. Businesses active in any sector, from finance to communications, manufacturing, food preparation, utilities, logistics, and mining, can rely on IoT.nxt’s framework to achieve successful digital transformation.

The IoT.nxt framework comprises software and applications, including the Commander device management platform and user interface, as well as the Raptor™ intelligent edge device that can perform as a gateway, data filter, and protocol translator. Raptor™ is produced in-house, leveraging state-of-the-art embedded design knowhow and surface-mount assembly technology.

With its many functions and multi-role flexibility, Raptor™ gives IoT.nxt a powerful advantage enabling the company to deliver effective end-to-end solutions within short timeframes. It represents an investment of considerable engineering resources and time, so applying the right hardware manufacturing and testing strategies has been critical to ensure profitability. Jaco Olivier, Embedded Team Leader at IoT.nxt, explains, “Using the correct testing strategy can save significant costs and expenses, while also helping meet quality requirements and reduce production lead times.”

The XJTAG boundary scan system is a powerful aspect of IoT.nxt’s testing strategy. “XJTAG is an excellent testing solution that helps us reduce development time and ensure the testability of our designs,” comments Jaco Olivier.

The embedded team at IoT.nxt is using XJTAG to test each board for physical and functional integrity. Willie Visage, Embedded Developer, takes up the story. “What takes months of development time for traditional testing methods takes less than a week using XJTAG. There is no need to work out a test solution, you simply describe the components on the board and how to interact with them. When we connect the XJLink2 controller, XJTAG manipulates the pins on all devices it can reach. It’s like inserting hundreds of little probes all over the circuitry. We just configure how the test is executed.”

XJLink2 has a standard 20-pin connector that can control up to four JTAG chains on the unit under test; alternatively, any spare pins can be used for general-purpose I/O to control signals such as system reset or power supply on/off. The JTAG signal pin positions are programmable, which further enhances flexibility.

“Developing test strategies with XJTAG is quick and effective,” continues Willie Visage. “It is integrated with the lifecycle of the product, so you develop from the start with testing in mind. It indicates clearly the test coverage it can achieve, and this can be as high as 80-90%.”

Jaco Olivier adds, “The excellent test coverage XJTAG achieves allows you to reduce the cost of test fixtures and XJTAG tests can be reused on multiple hardware designs, which saves immense time and resources.”

“Overall, XJTAG is easy to use and extremely efficient. It takes testing to the next level.”