Briton EMS uses XJTAG to pinpoint board faults

Briton EMS, a UK contract electronics manufacturer, is using the XJTAG boundary scan system to remove the guesswork from the test equation and rapidly pinpoint faults on complex and expensive printed circuit assemblies featuring high pin count ball grid arrays (BGAs).

Contract electronics manufacturers (CEMs) are investing in boundary scan test equipment to overcome the challenge of testing tightly-packed printed circuit boards populated with an ever increasing number of BGA components. Briton EMS selected the XJTAG system – ahead of competitive products – due to its price, ‘plug and play’ capability, reusability of scripts, and because of the responsiveness and proximity of XJTAG’s technical support.

“We opted for the XJTAG system because it is affordable, easy-to-use and requires no specialist training or dedicated operator as is the case with expensive X-ray systems,” said Simon Naylor, manufacturing director at Briton EMS. “The XJTAG system has enabled us to remove the guesswork from the test equation and provides a way of rapidly and accurately pinpointing faults on boards that failed their functional test. We have also been impressed by the level and quality of technical support from the XJTAG team – and it’s great that they are practically on our doorstep!”

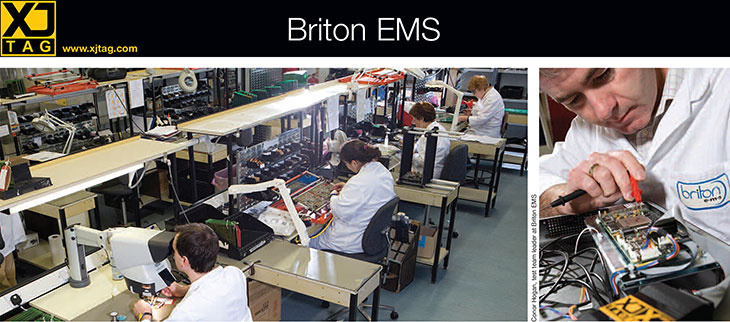

Briton EMS offers a broad range of electronics manufacturing services from printed circuit assembly through to complete product build, providing surface mount as well as conventional through-hole assembly. The company specialises in low to medium volume, high-mix production and also offers electronic and mechanical design services (hardware and software), prototyping, fulfilment and after-market services.

“We are delighted with the XJTAG system, in particular how easy it is to write test routines for devices and the fact that the same scripts can be reused on different projects,” added Conor Hogan, test team leader at Briton EMS. “This is a major benefit for a company that manufactures between 400 and 500 different boards each year, an increasing number of which feature one or more BGA devices.”

Briton EMS works in partnership with original equipment manufacturers (OEMs) across different markets including: broadcasting, industrial, instrumentation, medical and telecoms. The XJTAG system is used as a stand alone product and complements the company’s Ersascope BGA inspection system.

“XJTAG has transformed our test routine,” added Conor Hogan. “We have seen at first hand the benefit of using the JTAG chain to test our boards and we are now encouraging customers to populate their circuits with JTAG devices, where available, and to ensure that the devices are tracked on the board so that they can be accessed via the JTAG chain.”

The powerful and easy-to-use XJTAG boundary scan development system meets the growing market need for a cost-effective solution for testing tightly-packed printed circuit boards populated with JTAG devices such as BGA and chip scale devices, which cannot be tested by traditional methods.

XJTAG can test a high proportion of a circuit (JTAG as well as non-JTAG devices) including BGA and chip scale devices, SDRAMs, Ethernet controllers, video interfaces, Flash memories, FPGAs (Field Programmable Gate Arrays), microprocessors and many other devices. XJTAG also enables In-System Programming of FPGAs, CPLDs (Complex Programmable Logic Devices) and Flash memories.

The XJTAG system has enabled us to remove the guesswork from the test equation and provides a way of rapidly and accurately pinpointing faults on boards that failed their functional test. These boards typically feature one or several JTAG devices, such as FPGAs, which are inaccessible to probes and oscilloscopes.

Using the XJTAG system, we can now isolate a faulty device immediately and rework or reflow the failed component to rectify the problem. This saves us time and increases our yields.

Company: Briton EMS Limited

Nature of business:

Contract Electronics Manufacturer

Main product: Printed circuit assembly through to complete product build plus design services, prototyping, fulfilment & after-market services

Customers:

OEMs across broadcasting, industrial, instrumentation, medical and telecoms markets

Locations: Bedford, England

Employees: 90

Revenues: £7.5m

Web site: www.britonems.co.uk

Configure your products