Danish embedded innovator Mechatronic Brick maximises productivity with XJTAG

Small companies must respond effectively to customers’ needs, while always focusing on maximum productivity. As a highly focused team of eight, Denmark-based Mechatronic Brick is utilising the speed and user friendliness of XJTAG Boundary Scan Development and Test Platform to meet these demands and deliver specialised modules to developers of embedded systems.

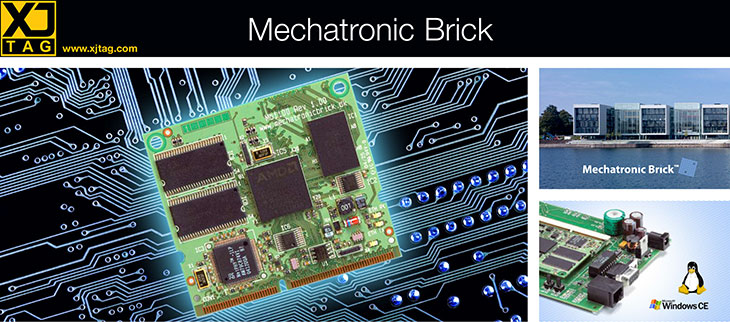

The small team at Mechatronic Brick’s headquarters in Sønderborg creates plug-in function modules that solve electronic, software and mechanical design challenges for customers developing embedded systems. The modules speed time to market and reduce development costs for control, communication and networking products by combining ARM-based processing with peripherals such as temperature sensing, A-to-D conversion, audio, USB or touch-sensor control. They can be delivered with Linux or Windows CE. Training and support for customers – covering all technologies used – are included, and the company also takes an active role in driver and application development.

Mechatronic Brick uses the XJTAG boundary scan system to test modules delivered from its manufacturing partner and then program the on-board Flash memory with bootloader, OS, custom software, MAC address and serial number. Taking advantage of XJTAG’s flexibility to integrate with other test techniques, engineers are able to control the boundary scan test routines from within the company’s custom test suite. The test suite software communicates with the target via the XJLink USB adapter and controls XJTAG to power-up and carry out a basic connection test. After the connection test all SDRAM, FLASH, real-time clock, non-volatile RAM, A-to-D converters and other components such as the watchdog, Ethernet PHY and touch controllers are tested using the flexible XJTAG test language, before finally the Flash is programmed.

“The power and flexibility of the XJEase programming language are major advantages of XJTAG, and contribute to very fast test execution,” comments Jørg Ulrich Hansen of Mechatronic Brick. “We are able to test 90% of the board within the first couple of seconds.”

Jørg Hansen and the team are using the XJRunner run-time-only environment to complete tests on production units arriving from the assembler. XJRunner delivers a reduced-cost solution for companies who need multiple boundary scan seats. “Our manufacturing partner also uses XJRunner to test and debug boards, and this helps our organisations to work together efficiently sharing a common test strategy.”

Test development is performed using the XJTAG Professional system, with features such as the XJDeveloper graphical environment with built-in testability analysis and the XJEase programming language assisting fast test development. “XJTAG has provided a large amount of downloadable example code, which helped us get started with the system very quickly,” says Jørg. “Moreover, XJTAG engineers helped us define the first set of tests for our circuits, and this was very beneficial to us. We felt that XJTAG understood our need for speed, and provided valuable help for us to achieve our goals.”

“Another valuable aspect to note is that the XJTAG license is held in the XJLink adapter, rather than on a PC, which makes the system very flexible and productive. This has helped us make the most of our investment in XJTAG,” he adds. “It provides a further example of the outstanding flexibility of this system, which combines with its many powerful and versatile features. We have found this to be a good test platform that has much to offer throughout development, production and field-maintenance environments”, he concludes.

The XJTAG trademark and logo are registered trademarks of XJTAG Ltd. All Rights Reserved. All other trademarks are the property of their respective owners.

The power and flexibility of the XJEase programming language enable very fast test execution. We are able to test 90% of the board within the first couple of seconds. A large amount of example code can be downloaded, which helped us get started with XJTAG very quickly. Moreover, XJTAG’s help to define our first test cases based on our circuits was very beneficial to us.

Because the license is held in the XJLink adapter, rather than on a PC, the system is very flexible and productive. The XJTAG platform has much to offer throughout development, production and field-maintenance environments.

Company: Mechatronic Brick, HQ Denmark

Nature of business: Electronics, software and technology in one solution; CPU modules for embedded systems; WinCE, Embedded Linux and other operating systems

Main product: Embedded CPU modules, Plug-in, custom mechatronic bricks

Customers: Embedded systems builders

Location: Sønderborg, Denmark

Employees: 8

Web site: www.mechatronicbrick.dk

Configure your products