Cambridge, UK, November 4, 2015 — XJTAG, a world leading supplier of boundary scan technology, will be previewing major new features of the XJTAG Development System in Hall A1, Booth 572, including Log File Viewer and Waveform Viewer.

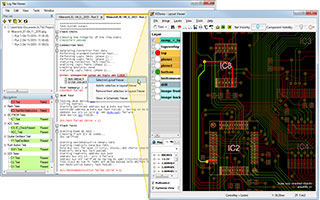

Working in conjunction with XJTAG’s production test environment, XJRunner, Log File Viewer successfully bridges the gap between the design domain and the production test environment by allowing test engineers to capture vital fault diagnosis and convey it back to design teams, enabling effective improvements in the Design for Manufacture and Test (DFM&T) process.

Log File Viewer goes beyond text, introducing an enhanced and interactive file format that enables log files to capture and record test data in a way that wasn’t previously possible. This greatly enhanced logging capability details all errors and includes embedded links to the Layout and Schematic Viewers, allowing Test and Design Engineers to more effectively visualise faults and their causes. The new format allows test data to be viewed by any engineer, long after the tests were actually performed, but with all the details normally available in the test output window.

John Hall, Software Development Manager at XJTAG, commented: “Log File Viewer significantly improves the way faults are recorded. It has been developed in response to customer requests to provide greater visibility of the cause of faults, in a way that can be used to support the entire product life cycle.”

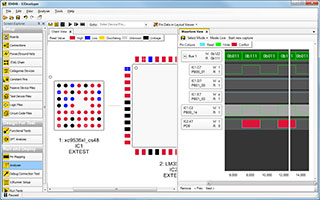

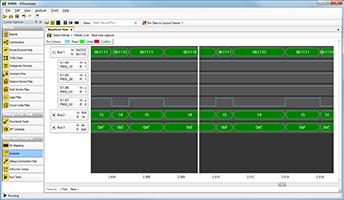

Alongside Log File Viewer, the latest release of XJTAG’s software suite will also include a new feature called Waveform Viewer, which provides the ability to view signal values and transitions in real time. The resulting debug information, which can be saved and reviewed by entire teams, also supports a high level of responsive interactivity, with intuitive navigation allowing engineering teams to find the information they need quickly and easily.

As well as displaying live data, the Waveform Viewer also supports triggering, enabling circuit behaviour to be recorded under user-specified conditions or when particular events occur. This powerful feature allows engineers to capture the key information needed to track down even intermittent faults on boards.

The new features are aimed at boosting the analytic capabilities of XJAnalyser and increasing both flexibility and usability in XJDeveloper and XJRunner. The latest version of the XJTAG Development System will be made available to all customers with a valid maintenance contract, evaluation versions are also available.

To find out more, visit www.xjtag.com or contact us at enquiries@xjtag.com.

For further information or article requests, please contact Philip Ling, Technical Marketing Manager, XJTAG (philip.ling@xjtag.com).

About XJTAG (www.xjtag.com)

XJTAG is a world leading supplier of JTAG boundary-scan hardware and software tools. The company focuses on innovative product development and high quality technical support. XJTAG products use IEEE Std.1149.x (JTAG boundary-scan) to enable engineers to debug, test and program electronic circuits quickly and easily. This can significantly shorten the electronic design, development and manufacturing processes.

XJTAG is based in Cambridge, UK, and since its first release of boundary scan tools in 2003 it has grown to deliver multi-million dollar sales worldwide. Clients across a wide range of industries benefit from using XJTAG products. These include aerospace, automotive, defence, medical, manufacturing, networking and telecommunications. The company sells and supports its products worldwide and works closely with over 50 experienced and professional distributors and technology partners across the globe. XJTAG is part of the Cambridge Technology Group.

Image (click for high resolution)