Are BGA Soldering Defects Wasting Your Time?

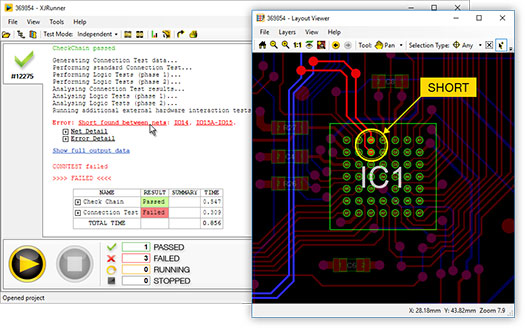

Use XJTAG’s PC tools to rapidly pinpoint faults

- Test BGA packages for soldering defects quickly and easily

- Achieve wide test coverage of your digital circuitry

- Identify open-circuit, short-circuit and “stuck-at” faults

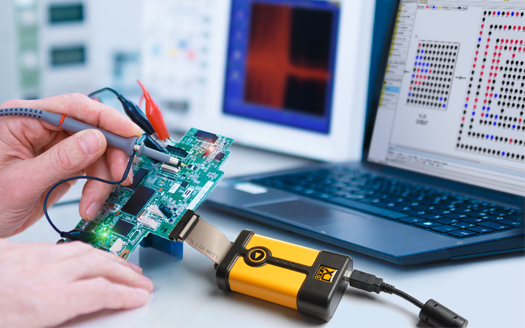

- Easy-to-use PC tool that connects over the JTAG interface

Try it for free

XJTAG makes BGA testing fast and effortless

Faster than X-ray BGA inspection

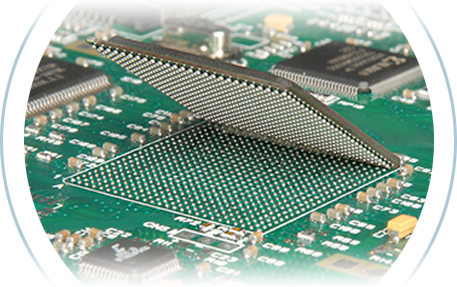

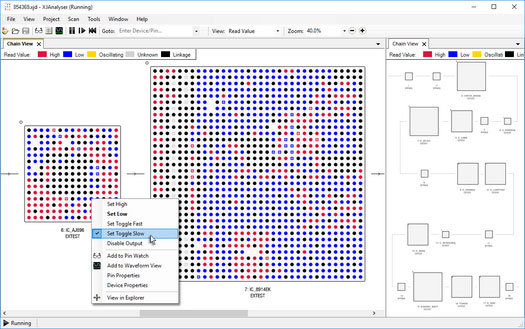

With XJTAG boundary scan testing you can quickly find BGA soldering defects without needing physical access. Easily control and monitor nets in real time – whether your board has 1 or 50 BGA (ball grid array) devices.

Pinpoint faults without wasted trips to the BGA rework station or an expensive X‑ray machine.

All using just one small connector.

Suitable for your first prototype

It doesn’t matter if a prototype was sent for manufacture before the design was finalised, or if a fluid specification means continual schematic changes. It’s easy to adapt tests to reflect board changes.

XJTAG testing works on boards with hand modifications and no-fit components.

No board firmware required

Quickly confirm the processor’s I/O pins and memory interfaces are working. Check memories and many other peripheral devices are operational, correctly assembled, and free from soldering defects.

All this without having written one line of code.

Recover dead boards

Even if the processor won’t boot, XJTAG’s boundary scan tests will still run if it has a working JTAG interface.

It doesn’t matter if the memory interface is faulty or the clock won’t oscillate.

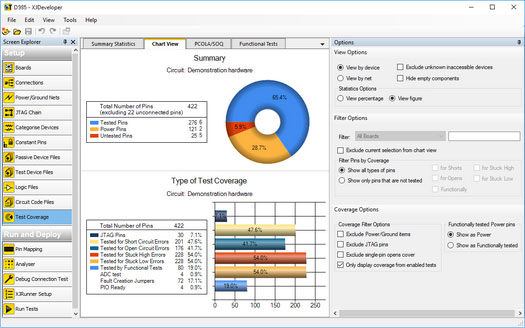

High Test Coverage

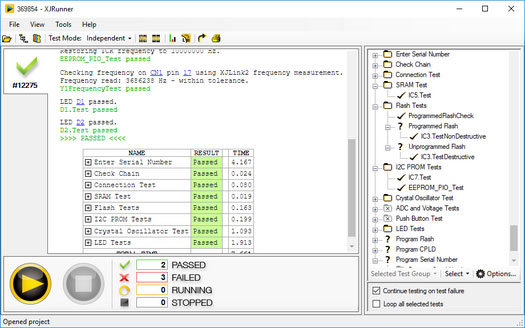

XJTAG can test digital circuits far beyond the JTAG-enabled microprocessor or FPGA. It will check for assembly faults on RAM, flash memory, EEPROMs, logic gates, and devices connected over SPI, I²C or parallel interfaces.

Automated analysis provides statistics on how much of your circuit board can be tested.

No BGA X-ray Machine? No Worries.

Identify PCB assembly faults easily and at lower cost

- Detect soldering defects on a BGA’s balls without physical access

- Check JTAG-enabled devices, memories, logic & digital peripherals

- No firmware needs to run on the board

- Intuitive interface – little or no training required

- Runs without a test jig

- Find faults that BGA X-ray machines fail to spot

- Boundary scan is supported by all FPGAs, CPLDs & most 32-bit microprocessors

Any questions?

Configure your products