Featured Capabilities

Advanced Interconnection Test

Introduction

An interconnection test is a vital part of any testing suite, checking that components are properly soldered onto the board and that there are no short circuits. The test is normally automatically generated from the circuit data provided to the test tool. XJTAG calls its version of this ‘Connection Test’.

Improved connectivity testing

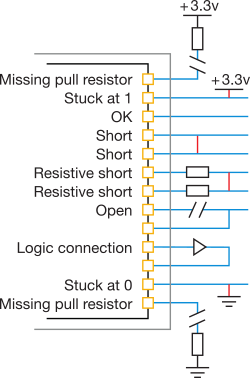

XJTAG’s Connection Test detects PCB faults in three categories: short circuit, open circuit and stuck-at faults. While these are the same categories of faults that are identified by other interconnection tests, XJTAG is able to identify more faults and indicate their positions more precisely.

ATPG “On The Fly”

Connection Test generates its test patterns each time it is run. Using Automatic Test Pattern Generation (ATPG) means that any design modifications to the board can be quickly and easily incorporated without the need to have a new set of tests developed by your test vendor.

Test Beyond Resistors

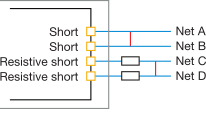

This diagram shows a situation that causes a major problem for many JTAG interconnection tests. Traditionally, the test industry drove conflicting values on nets in order to find short circuits. While the conflict-based algorithm is able to identify the short circuit between nets A and B, the inline resistors in nets C and D mean that the short circuit between those two nets is not detected. XJTAG’s Connection Test uses an algorithm which overcomes this problem.

Diagnostics as standard

High precision fault diagnostic capabilities are included as standard. When Connection Test finds a fault it will display the type of fault found, the nets and pins involved and provide links into the layout and schematic of the board to help the engineer repairing the board, as well as allowing access to the data driven and read from the UUT during the test which caused the test to diagnose the fault.

For support, or for a quote on any part of the XJTAG system, please contact us.

Configure your products